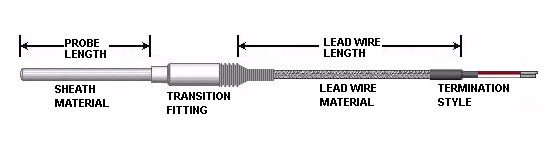

Mineral Insulated Thermocouples with Lead Wires

(Series TL1)

Ordering Information

Configure this style to request a quote or call for assistance

Part No.:

select options

Start Here

| 1 Series |

2 Calibration |

3 Sheath Diameter |

4 Sheath Material |

5 6 Sheath Length |

7 Junction |

8 Transition Fitting |

9 Lead Wire Material |

10 Lead Wire Length |

11 Termination Style |

12 Special Features |

13 Attached Fitting |

14 15 Insertion Length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TL1 |

| 2 | Calibration |

|---|---|

| J | Type J |

| K | Type K |

| T | Type T |

| E | Type E |

| W | Type J (Special limits) |

| X | Type K (Special limits) |

| Y | Type T (Special limits) |

| Z | Type E (Special limits) |

| 3 | Sheath Diameter |

|---|---|

| A | 0.032" (0.8mm) |

| B | 0.040" (1mm) |

| C | 0.059" (1.5mm) |

| D | 0.062" (1.6mm)(1/16") |

| E | 0.079" (2mm) |

| F | 0.092" (2.3mm) |

| G | 0.118" (3mm) |

| H | 0.125" (3.2mm) (1/8") |

| J | 0.156" (4mm) |

| K | 0.177" (4.5mm) |

| L | 0.188" (4.8mm) (3/16") (standard) |

| M | 0.236" (6mm) |

| N | 0.250" (6.4mm) (1/4") |

| P | 0.314" (8mm) (5/16") |

| Q | 0.375" (9.5mm) (3/8") |

| Sizes for reference only (Standard tolerances apply) | |

| For other diameters consult factory |

| 4 | Sheath Material |

|---|---|

| F | 304 SS |

| H | 316 SS |

| M | INCONEL (600) |

| N | 446 SS |

| P | 310 SS |

| Q | Hastelloy |

| R | Pyrosil D |

| 5 6 | Sheath Length |

|---|---|

| ¼-600 |

| 7 | Junction |

|---|---|

| G |  Grounded (Single)

Grounded (Single) |

| U |  Ungrounded (Single)

Ungrounded (Single) |

| E |  Exposed (Single)

Exposed (Single) |

| R |  Exposed & recessed (Single)

Exposed & recessed (Single) |

| W |  Grounded (Dual)

Grounded (Dual) |

| X |  Ungrounded & isolated (Dual)

Ungrounded & isolated (Dual) |

| Y |  Ungrounded common (Dual)

Ungrounded common (Dual) |

| Z |  Expose & isolated (Dual)

Expose & isolated (Dual) |

| Ungrounded and isolated only available in 0.156" OD & larger |

| 8 | Transition Fitting |

|---|---|

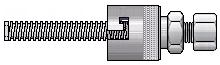

| 1 |  3/8”OD X 1.25” w/ strain relief spring

3/8”OD X 1.25” w/ strain relief spring |

| 2 |  1/4”OD X 1.25” w/ strain relief spring

1/4”OD X 1.25” w/ strain relief spring |

| 3 |  3/16”OD X 1” w/ strain relief spring

3/16”OD X 1” w/ strain relief spring |

| 4 |  3/8”OD X 1.25” (no spring)

3/8”OD X 1.25” (no spring) |

| 5 |  1/4”OD X 1.25” (no spring)

1/4”OD X 1.25” (no spring) |

| 6 |  3/16”OD X 1” (no spring)

3/16”OD X 1” (no spring) |

| 7 |  7/16”OD X 2” (no spring)

7/16”OD X 2” (no spring) |

| 8 |  3/8”OD X 2” (no spring)

3/8”OD X 2” (no spring) |

| 500°F epoxy standard | |

| See special features for ceramic potting |

| 9 | Lead Wire Material |

|---|---|

| A |  Fiberglass (800°F)

Fiberglass (800°F) |

| B |  Fluoropolymer (400°F)

Fluoropolymer (400°F) |

| C |  Polyimide (500°F)

Polyimide (500°F) |

| D |  PVC (220°F) PVC (220°F) |

| E |  High temperature fiberglass (1200°F)

High temperature fiberglass (1200°F) |

| F |  Fiberglass with stainless steel braid (800°F)

Fiberglass with stainless steel braid (800°F) |

| G |  Fluoropolymer with stainless steel braid (400°F)

Fluoropolymer with stainless steel braid (400°F) |

| H |  Fiberglass with armor cable (800°F) Fiberglass with armor cable (800°F) |

| J |  Fluoropolymer with armor cable (400°F)

Fluoropolymer with armor cable (400°F) |

| K |  Polyimide with armor cable (500°F)

Polyimide with armor cable (500°F) |

| L |  High temperature fiberglass with armor cable (1200°F)

High temperature fiberglass with armor cable (1200°F) |

| M |  Fiberglass with stainless steel braid with armor cable (800°F)

Fiberglass with stainless steel braid with armor cable (800°F) |

| W |  Fluoropolymer with stainless steel braid with armor cable (400°F)

Fluoropolymer with stainless steel braid with armor cable (400°F) |

| X |  High temp fiberglass with ss steel braid (1200°F)

High temp fiberglass with ss steel braid (1200°F) |

| Wire gauge determined by ECS based on sheath diameter |

| 10 | Lead Wire Length |

|---|---|

| 6-999 | |

| Over 999" contact factory |

| 11 | Termination Style |

|---|---|

| A |  2" stripped leads (bare ends)

2" stripped leads (bare ends) |

| B |  2" stripped leads w/ spade lugs

2" stripped leads w/ spade lugs |

| C |  Standard male plug (400°F)

Standard male plug (400°F) |

| D |  High temp male plug (660°F)

High temp male plug (660°F) |

| E |  Max temp male plug (800°F)

Max temp male plug (800°F) |

| F |  Ceramic male plug (1200°F)

Ceramic male plug (1200°F) |

| G |  Solid pin plug

Solid pin plug |

| H |  Standard female jack (400°F)

Standard female jack (400°F) |

| J |  Miniature plug (400°F)

Miniature plug (400°F) |

| K |  Miniature jack (400°F)

Miniature jack (400°F) |

| L |  2" stripped leads w/ #6 Ring terminals

2" stripped leads w/ #6 Ring terminals |

| N |  Standard 3 pin plug w/ ground wire (400°F)

Standard 3 pin plug w/ ground wire (400°F) |

| P |  Dual molded male plug (400°F)

Dual molded male plug (400°F) |

| W |  2” stripped leads w/ pin terminals

2” stripped leads w/ pin terminals |

| Q |  2” stripped leads w/ wire ferrules

2” stripped leads w/ wire ferrules |

X |

Extra long lead wire length (beyond 2” stripped leads)

Extra long lead wire length (beyond 2” stripped leads) |

| 12 | Special Features |

|---|---|

| None | |

| 47 |  Stranded conductor (Lead wire)

Stranded conductor (Lead wire) |

| 04 |  Flat tip probe

Flat tip probe |

| 07 |  Cable Clamp

Cable Clamp |

| 08 |  Bx Connector

Bx Connector |

| 09 |  Mating connector

Mating connector |

| 10 |  Armor cable adapter

Armor cable adapter |

| 11 |  International IEC 584-3 color coded leads

International IEC 584-3 color coded leads |

| 12 |  British color coded leads

British color coded leads |

| 13 |  German color coded leads

German color coded leads |

| 14 |  Japanese color coded leads

Japanese color coded leads |

| 15 | Reverse polarity color coded leads |

| 16 |  French color coded leads

French color coded leads |

| 18 |  Moisture protection boot on connector

Moisture protection boot on connector |

| 19 |  High temperature ceramic potting (1200°F)

High temperature ceramic potting (1200°F) |

| 21 |  Fluoropolymer coated armor cable (Fluoropolymer)

Fluoropolymer coated armor cable (Fluoropolymer) |

| 24 |  Fluoropolymer covered probe

Fluoropolymer covered probe |

| 25 |  Free spinning fitting (held on probe by a crimp ring)

Free spinning fitting (held on probe by a crimp ring) |

| 28 |  90 degree bend

90 degree bend |

| 30 |  45 degree bend

45 degree bend |

| 13 | Attached Fitting (optional) |

|---|---|

| None | |

| F01 |  1/8" npt single thread

1/8" npt single thread |

| F02 |  1/4" npt single thread

1/4" npt single thread |

| F03 |  3/8" npt single thread

3/8" npt single thread |

| F04 |  1/2" npt single thread

1/2" npt single thread |

| F05 |  3/4" npt single thread

3/4" npt single thread |

| F06 |  1/2" npt x 1/2" npt double thread

1/2" npt x 1/2" npt double thread |

| F07 |  1/2" npt double thread. Spring loaded

1/2" npt double thread. Spring loaded |

| F08 |  1/2" npt x 1/2" npt double thread. Spring loaded w/ oil seal

1/2" npt x 1/2" npt double thread. Spring loaded w/ oil seal |

| F09 |  1/2" npt x 3/4" npt double thread

1/2" npt x 3/4" npt double thread |

| F10 |  3/4" npt x 3/4" npt double thread

3/4" npt x 3/4" npt double thread |

| F11 |  Fixed bayonet cap assembly

Fixed bayonet cap assembly |

| F14 |  1/2" npt x 1" npt double thread

1/2" npt x 1" npt double thread |

| F15 |  1" npt single thread

1" npt single thread |

| F16 |  Adjustable 7/16" ID bayonet cap fitting (1/8" OD & 3mm OD)

Adjustable 7/16" ID bayonet cap fitting (1/8" OD & 3mm OD) |

| F17 |  Adjustable 12.5mm ID double slot bayonet cap fitting (1/8" OD & 3mm OD)

Adjustable 12.5mm ID double slot bayonet cap fitting (1/8" OD & 3mm OD) |

| F18 |  1/8" npt compression fitting (Brass)

1/8" npt compression fitting (Brass) |

| F19 |  1/8" npt compression fitting (Stainless Steel)

1/8" npt compression fitting (Stainless Steel) |

| F20 |  1/4" npt compression fitting (Brass)

1/4" npt compression fitting (Brass) |

| F21 |  1/4" npt compression fitting (Stainless Steel)

1/4" npt compression fitting (Stainless Steel) |

| F22 |  1/2" npt compression fitting (Brass)

1/2" npt compression fitting (Brass) |

| F23 |  1/2" npt compression fitting (Stainless Steel)

1/2" npt compression fitting (Stainless Steel) |

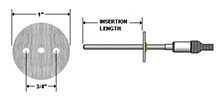

| F28 |  1" circular mounting flange

1" circular mounting flange |

| For other fittings not shown contact factory |

| 14 15 | Insertion Length (when required) |

|---|---|

| None | |

| 1-144 |

- Solid wire is standard on MGO extension thermocouples

- For stranded wire see special features